A Philosophy Defining Our Calling

WOOD

FOR

GOOD

Since 1932, we have been working with wood, which has been the foundation of our family business for the past 90 years, always using the same raw material.

We design and develop patents based on circular economy principles and comply with the most stringent international eco-environmental regulations.

The products we manufacture at VISSUALLY can be made from FSC certified MDF/HDF wood fibre, with a density per m3 ranging from 750 to 900 kg.

Digital printing allows us to customize each project in an original, different, and exclusive way with finishes that simulate wood, metals, colors, and more. In essence, endless possibilities that ultimately make the display stand out for the brand, adding a higher level of prestige to the exhibited products, while maintaining a perpetual quality like the first day.

The use of this printing technique eliminates the need for clichés, which eventually become useless waste, in comparison to the efficiency and top quality offered by digital printing.

It's an immense satisfaction for us to see the achieved result by properly combining these innovative technologies with our patented system, enabling us to create unique and exclusive products for each client across multiple sectors. These products are sustainable, environmentally friendly, and reusable, utilizing the minimum necessary raw materials and consuming minimal electricity.

In addition to the benefits of cauterizing the entire perimeter of the products, laser cutting allows us to create short runs and special shapes that make each display unique and exclusive for every customer.

This cutting system avoids the use of consumables like band saws or circular saws, and eliminates costs such as dyes for cardboard. This is especially significant for short production runs, as these costs can add up significantly.

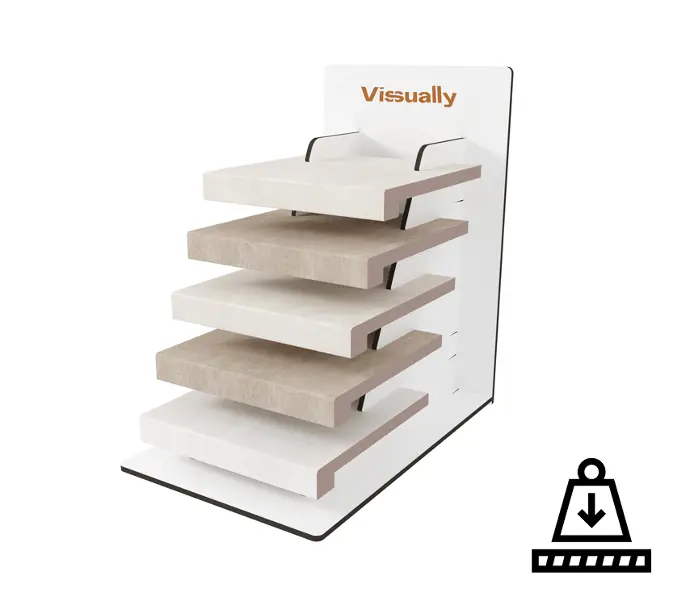

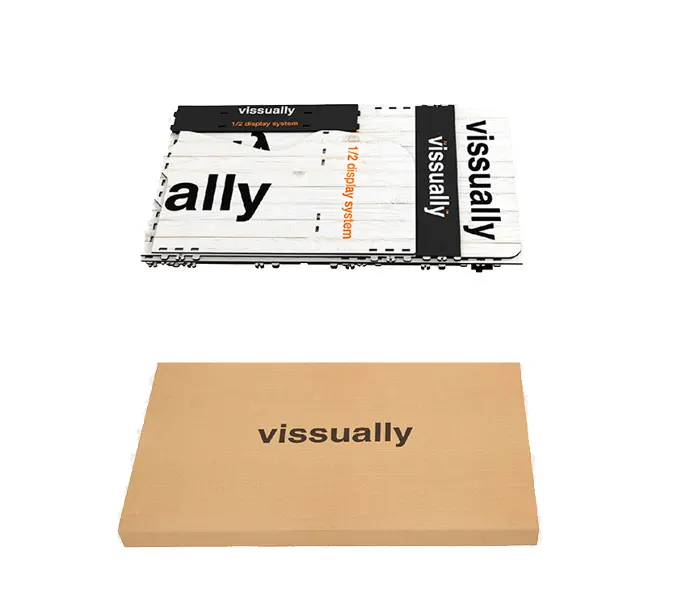

Allowssavings of 85% in storage costs, 75% in transportation costs, and up to 50% in assembly costs compared to a fully assembled display.

When comparing these figures with those of cardboard displays, the difference is up to 5 times greater. The strength and durability of VISSUALLY displays easily extend to a lifespan of 10 years or more, while retaining nearly the same quality as the first day.

Easy to assemble and disassemble, can be stored flat.

TRADITION + PASSION + ECO-INNOVATION = VISUALLY

We have been working with wood since 1932, this has been the basis of our family business for the last 90 years, always using the same raw material.

During this extensive and immense experience, we have suffered through a civil war, fires, economic crises, earthquakes, pandemics that have devastated us, having to "start over" on several occasions again, but always with the same enthusiasm and with infinite passion, we have once again chosen as the only option to always work with wood and its derivatives.

At the same time that the creation of new products and various applications has evolved, we have incorporated and adapted at all times the latest generation technologies to transform wood into a final product of excellent quality and finishes, we have gone from cutting with a saw from tape to using laser cutting technology, from printing with bronze clichés to high-definition digital printers.

In the last 25 years we have registered several international patents that have allowed us to manufacture eco-innovative products with total exclusivity.

Turn Your Ideas Into Products

Qclick easy assembly and disassembly

Strong and Durable

Weight-bearing displays

Recycled and 100% recyclable

Our Eco Efficient System ½

Flat Storage

Merchandising

Wood Displays

Advantages and characteristics of displays and other VISSUALLY products

The products that we manufacture at VISSUALLY are made of 100% renewable wood fiber, MDF/HDF with a density per m3 ranging between 750 and 900 kg.

If we compare these data with those of the cardboard displays, the difference is up to 5 times greater. The resistance and durability of the VISSUALLY displays easily reaches 10 years of useful life, without practically losing the quality of the first day.

At the level of floor displays, we have an added advantage provided by laser cutting, which is that when the cut is made, the entire perimeter is cauterized and this sealing effect greatly limits moisture absorption, giving it greater stability and longevity, either for Uses in stores, department stores or supermarkets, when daily cleaning is carried out, other less resistant materials absorb moisture and deteriorate very easily, losing stability and visual presence, weakening the brand image.

Another great advantage that wood fiber provides, compared to other materials, including sawn wood, is that splinters are not generated, which can be very annoying if a customer or consumer gets stuck in them while using displays or packaging. Cardboard also has the drawback that its edge generates a knife-like edge that can also cause accidents during assembly or use by end consumers.

The products that are marketed under the VISSUALLY brand comply with the strictest international environmental regulations, providing our customers with products based on the strictest Eco-design premises of the so-called "Circular Economy" greatly reducing emissions and improving their carbon footprint. carbon significantly.

Laser Cutting Technology

Laser cutting, apart from the advantages of cauterizing the entire perimeter of the products, allows us to make short runs and also special shapes that make each display unique and exclusive for each client.

This cutting system avoids the use of consumables such as band or circular saws, or costs to be passed on such as dies in the case of cardboard, eliminating the costs of these that are very important for the realization of short runs.